The Goodyear Tire & Rubber Company has turned to rice husk waste to aid its tire making business. Goodyear today announced it will utilize ash left over from the burning of rice husks to produce electricity as an environmentally friendly source of silica for use in its tires.

The company has tested silica derived from rice husk ash over the past two years at its Innovation Center here and found its impact on tire performance to be equal to traditional sources. Goodyear is negotiating with potential suppliers to purchase rice husk ash silica for use in its tires. Silica is mixed with rubber in tire treads to increase the rubber’s strength and help reduce rolling resistance, which improves fuel economy. It also can have a positive impact on a tire’s traction on wet surfaces.

“The use of rice husk ash will provide Goodyear an alternative source of silica while helping reduce the amount of rice husk waste being landfilled,” said Joseph Zekoski, Interim Chief Technical Officer. “This illustrates Goodyear’s commitment to innovation and to the environment.”

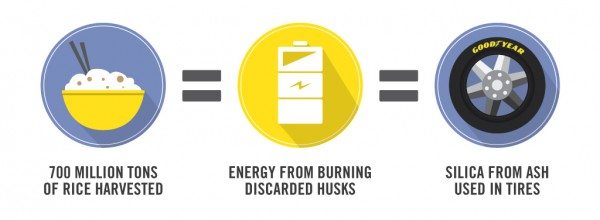

Each year, more than 700 million tons of rice is harvested worldwide, according to the Food and Agricultural Organization of the United Nations, and disposing of the rice husks is an environmental challenge. As a result, husks often are burned to generate electricity and reduce the amount of waste shipped to landfills.

“Goodyear’s innovation efforts are focused on making tires more environmentally friendly – in their materials, in their performance and in the manufacturing process,” said Zekoski. “For example, we continue to explore ways to increase the fuel efficiency of tires. We strive to help consumers keep their tires operating optimally, through innovations such as Air Maintenance Technology (AMT). And we look to renewable resources, including soy bean oil, to replace petroleum-based materials in tires.”