JLR has started deploying drones inside its factories, and the results are already making a big difference. What used to take hours is now done in minutes, with perhaps the biggest win coming from better safety for the team working on the ground. This new trial runs at the Electric Propulsion Manufacturing Centre in Wolverhampton and is a small but clear step toward how JLR wants its factories to work in the future.

This helps the engineers view areas that are otherwise high, tight, or hard to access. Instead of climbing onto platforms or entering narrow spots, the team is now able to inspect everything from the floor. It saves time, lowers the risk and allows them to spot issues earlier.

Key Things Drones Can Do

- Cut a four-hour inspection job down to about 10 minutes.

- Safely fly into high or confined spaces.

- Create live 3D maps with LiDAR.

- Look for overheating parts or insulation issues using a thermal camera.

- Catch problems early and reduce down time.

- Free up workers to perform jobs that are more important.

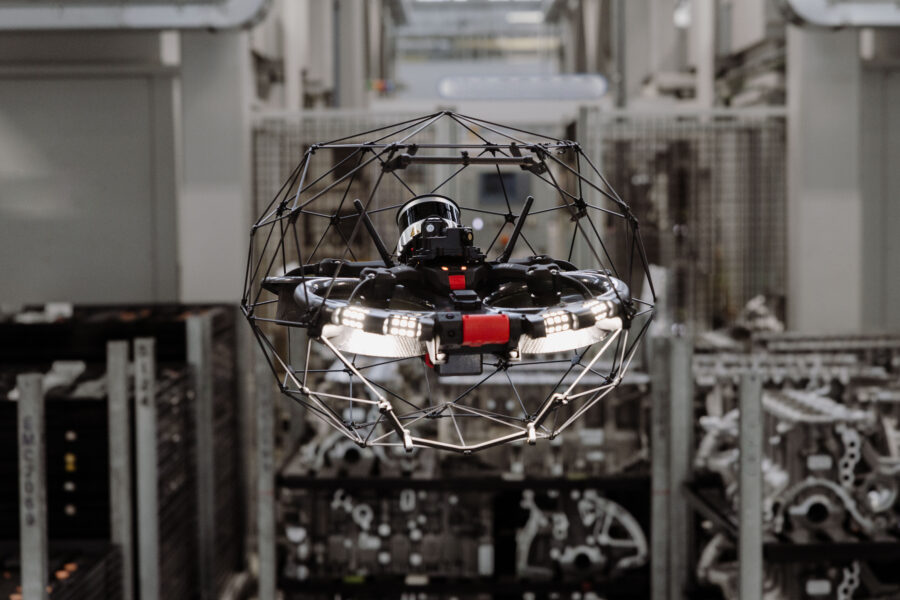

The drone used in the trial is the Elios 3 from Flyability. Designed for indoor environments, it is controlled through a tablet. Moving along, it sends out laser pulses to build a detailed 3D picture of the factory. If there’s a hotspot or something overheating, the thermal camera shows it instantly. This helps JLR reduce energy waste and lower operational emissions, too.

Nigel Blenkinsop, Executive Director of Industrial Operations, said that this trial was part of the rethinking of how JLR runs its facilities. It improves safety, cuts downtime, and he added it helps employees learn new digital skills important for the future.

This is unfamiliar territory for most employees. In fact, Shantnu Mehta, Project Engineer at JLR, mentioned that he never would have imagined learning to fly a drone for work, but now such skills will remain in his toolbox throughout his life and professional career.

What happens next

The next test will be held at the huge Logistics Operations Centre in Solihull – a warehouse almost as big as thirteen football fields. That is where the drone will get a barcode scanner to automate inventory checks. The advantages are obvious: faster stock updates, fewer errors, and safer working conditions.

This project is also part of JLR’s long-term investment in innovation, modernisation and upskilling. Over the next few years, it plans to train 29,000 employees in electrification and digital technologies.

Conclusion

This may look like a small drone pilot, but it shows where JLR is heading: smarter factories, safer workplaces, and faster operations. And above all, people and technology working alongside each other in shaping the future of JLR.