It’s World Environment Day and vehicle manufacturers in the country are taking various steps to promote eco-friendly ways and celebrate the occasion. Here’s a compilation of all the official announcements of what the manufacturers are doing to celebrate the 2018 World Environment Day.

Volkswagen India builds an environment-friendly primary school

Volkswagen India announced the inauguration of a new primary school building in Phadke-Wasti, Nighoje helping provide excellent education facilities to growing communities in the emerging industrial zone of Chakan, Pune. Developed solely by Volkswagen India as part of their larger CSR initiative towards education and skill development, the school can cater up to 120 students every year. The environment-friendly primary school was inaugurated on June 05, 2018.

The new building has two floors and will offer one room for each of the four standards in the primary school where previously one room was being shared by two grades. Volkswagen Plant Engineering architect has designed the new building which is designed to accommodate a higher number of students than before. The new building has separate rooms for indoor extra-curricular activities and the staff. The school premises has a kitchen to provide mid-day meal for the students.

The school is also equipped with its own rainwater harvesting system and greywater treatment system that will enable cana and banana plants to grow on campus.

This new building will be certified by the Indian Green Building Council and is expected to receive either a Silver or Gold rating.

Tata Motors comes one step closer towards automotive electrification in Madhya Pradesh

Tata Motors Limited, with EESL, handed over two Tigor Electric Vehicles (EVs) to the Madhya Pradesh Government.

This development comes to light closely after Tata Motors signed a Memorandum of Understanding (MoU) with the State Government of Maharashtra for deployment of 1000 Electric Vehicles (EV) across its range of passenger and commercial vehicles in the State.

With Tigor EV, Tata Motors has marked the beginning of their journey in boosting e-mobility and will soon offer a full range of electric vehicles to Indian customers. The company’s collaborative working operations are dedicated towards boosting the adoption of EVs along with building a sustainable future for India.

Tata Motors is committed to the Government’s vision for electric vehicles by 2030 and will work in a collaborative manner to facilitate faster adoption of electric vehicles and to build a sustainable future for India.

Maruti Suzuki innovations to reduce emissions and water use

Maruti Suzuki India has introduced a series of innovations across its products and manufacturing processes that contain emission and lower water use.

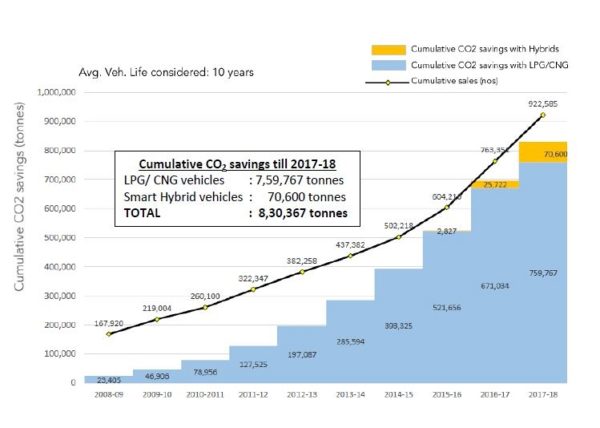

The Company has saved an estimated over 8.3 lakh tonnes of CO2 emission over the past decade through introduction of CNG, LPG and Smart Hybrid vehicles.

Maruti Suzuki has been consistently achieving improvements in fuel efficiency in the conventional petrol engine and diesel engine vehicles. The efforts have led to nearly 20% fuel efficiency improvement in compact cars in both gasoline and diesel vehicles. This is achieved through focused innovations such as new generation platforms, friction reduction in drive train and improvement in drive-line losses.

The innovative next generation HEARTECT platform lowers the CO2 emission by 6-8% while offering superior performance and safety. Blockbuster models such as the Baleno, IGNIS, Swift and Dzire, built on the HEARTECT platform, are thus more efficient with superior performance. These models meet the advanced safety norms, leading to a win-win for customers and the environment.

At its manufacturing facilities, Maruti Suzuki has reduced water consumption per vehicle manufactured by 6% in 2017-18, compared to the previous year. At the same time, there is a 1% reduction in CO2 emission while manufacturing every vehicle over the past year.

Use of Maruti Suzuki’s Dry Wash system, saved a whopping 285 million litres water in 2017-18. Nearly, 3 million vehicles were cleaned using Dry Wash system in 2017-18. Maruti Suzuki uses the environment friendly Dry Wash system to conserve water, shorten wash time and improve final wash quality. Presently, 588 Maruti Suzuki workshops across 186 cities use the Dry Wash system.

On product designing, Maruti Suzuki has developed the full vehicle virtual validation capability, which has helped to induce efficiency in the product development processes. This leads to reduced physical testing of vehicles. Such virtual validation techniques help to reduce carbon footprint.

Maruti Suzuki has a stringent Green Procurement Policy in place where in all partners are encouraged to align with Green Procurement guidelines. More than 85% vendor plants have already acquired ISO -14001 Certification and others are on course.

The Company will soon adopt International Material Data capturing system to study parameters like ASR (Automotive Shredder Residue), RRR (Reuse, Recycle and Recover) and substances of concern (like Pb, Hg, Cd, Cr) across all models so that prohibited substances can be identified and eliminated. This initiative will strengthen end of life system (ELV) for vehicles.

For exports Maruti Suzuki will align with the European Union system of classification, labelling and packaging of chemical substances adopt VCI Packaging (Volatile Corrosion Inhibitors) guidelines for packaging materials. By aligning with EU norms the disclosures on components will be comprehensive.

Daimler Buses India continues sustainable growth, upgrades flagship product

Daimler Buses India, a unit of Daimler Buses under the umbrella of Daimler India Commercial Vehicles (DICV), is moving ahead on its sustainable growth path. In 2017, strong growth was recorded with domestic sales of 906 units (2016: 501 units, +80 percent) despite a significant drop of the total bus market in India. For 2018, Daimler Buses India expects a continuing positive development of unit sales.

Daimler Buses India’s product portfolio comprises BharatBenz 9-tonne buses in the school, staff and tourist bus subsegments, Mercedes-Benz 15-meter multi-axle luxury coaches and bus chassis for the 9, 16 and 24-tonne segments. Bus chassis for the 9 and 16-tonne segments are also exported to markets in Africa, Latin America, the Middle East, and South East Asia.

With the presentation of the new-generation of its flagship product, the Mercedes-Benz 2441 SHD (Super High Deck) Automatic coach, Daimler Buses India raises the bar further in the segment. India’s longest luxury coach (15 meters) now comes with even more power and comfort thanks to an upgradeto higher power (+50 hp) with automatic transmission, which provides for further improvedfuel efficiency and an even smoother and quieter ride for passengers at the same time.

The Mercedes-Benz 2441 SHD Automatic luxury coach offers a high seating capacity of up to 59 pushback seats and 14 cubic meters of luggage space. Built with a unique aluminique body, it is the lightest vehicle in its class which contributes to fuel efficiency. With an active steerable tag axle, it features a low turning circle diameter to effortlessly navigate sharp turns and bends. It also has an advanced braking system and a strategically positioned fuel tank for added safety.

Hyundai Joins Hands for ‘Beating Plastic Pollution’ on World Environment Day 2018

Hyundai Motor India Ltd. (HMIL), the country’s second largest car manufacturer and the number one car exporter since inception announced its initiatives supporting the cause ‘Beating Plastic Pollution’ on ‘World Environment Day 2018’ along with free PUC, Emission check and Dry Wash for Hyundai Cars on 5th June.

In-line with the global theme of ‘Beating Plastic Pollution’, Hyundai’s initiatives will focus on reducing the usage of plastics at its manufacturing plant in Sriperumbudur near Chennai and across all its 493 Hyundai Dealerships and 1309 Service Workshops. Hyundai along with its vendor partners will also opt for alternate packaging material for spare parts and usage of water-borne paints. Alongside, Hyundai Dealer Workshops will conduct environment friendly activities to engage and create awareness among the customers & employees for the reduction in use of plastics, usage of LED’s that consume up to 80% less energy and Proper disposal of waste material.

Hyundai encourages its valuable customers to opt dry wash for their Hyundai car during service thereby saving approx.120 litres per car. Last year, Hyundai launched a 45 days campaign – ‘Save Water, Share Water’ across India thus saving 40 lakhs litres of Water through Dry wash and distributed the same in drought affected areas in Tamil Nadu and Andhra Pradesh. Hyundai has introduced these initiatives to conserve water Hyundai has introduced these initiatives to conserve water, control pollution and conserve energy across its network. Hyundai offers – Free Dry wash for cars, Free PUC and Emission check on 5th June 2018 for customers at workshops across India.

Honda 2Wheelers India launches nationwide campaign to celebrates World Environment Week 2018

On the occasion of 46th World Environment Day, Honda Motorcycle & Scooter India Pvt. Ltd. (HMSI) in collaboration with Society of Indian Automobile Manufactures (SIAM) kick started its week long National campaign #hondabeatspollution. The week long campaign, starting June 5th, will be effective at Honda’s authorized dealership network of 5700 touchpoints across India.

Not just at its dealership network, Honda conducted activities across its plants in Manesar (Haryana), Tapukara (Rajasthan) Narsapura (Karnataka) and Vithalapur (Gujarat).

Under this week long campaign, special initiatives are planned at 5700+ touchpoints network including and society at large. Honda will be engaging with its dealership network for plantation of saplings at their premises, nearby schools and primary localities. As part of its commitment towards environment, free of cost PUC check-ups will be conducted for all the customers visiting Honda authorized workshops. Free plant saplings will be given away to customers visiting the dealerships. At various schools, engagement with students will be conducted through the format of quiz, art competitions and rallies along with plantation drives.

In line with this year’s UNEP theme, ‘Beating Plastic Pollution’, Honda took a holistic approach towards environment preservation through its concept of Green Factory, Green Dealer and Green Supplier, aiming for a Cleaner, Greener and brighter outlook. Various employee engagement programs and awareness trainings were organised to create a consciousness for the environment.

To further engage with customers, workshop employees will be wearing badges and T-Shirts with a message of ‘conserve and protect the environment’ and special banners will be placed outside showrooms, dealerships and workshops to further promote the campaign.

Yamaha reiterates it commitment for Environment Protection; organises pollution check-up camps at 23 dealerships across India

On the occasion of World Environment Day, India’s leading two-wheeler manufacturer, Yamaha Motor India Group (YMIG) on Tuesday started its week long celebrations (June 5- June 11) at its plants and dealerships nationally. Following the United Nation’s theme for this year ‘Beat Plastic Pollution’, the company organized numerous activities and contests to create awareness amongst its employees on exploring sustainable alternatives and reduce plastic waste by avoid using single-use plastic items.

As a part of this event, the employees were imparted training on the Plastic Waste Management Rules 2016. During the session, employees were educated on the disadvantages of using plastic, how plastic waste poses a big threat to the environment and ways to reduce plastic waste. In addition to this, Yamaha planted 100 trees along with a distribution of 5000 ‘Tulsi’ saplings amongst its employees, dealers and customers across India. Free Pollution Check-up camps were also conducted at Yamaha’s 23 dealerships in various cities including Delhi, Hyderabad, Ahmedabad, Bengaluru, Assam etc.

On the day of commencement, all the Yamaha employees took a pledge to protect the environment by adopting eco-friendly processes for a better tomorrow. Some of the activities conducted across all locations included Online Environmental Quiz, Display of Cloth Banners, Sharing Environmental Tips mailers with employees, Screening of Environment Promotional Video, Tree Plantation etc. The employees got an opportunity to show their passion and contribution towards the initiative through environmental promotional competitions.

Yamaha encourages optimum usage of limited resources and does take innovative and effective measures to meet the objectives of Sustainable Development. The principle of Reduce, Reuse & Recycle of resources are adopted at Yamaha to promote sustainable development, consumption and production. The company is actively contributing to build a clean and green future through the environment-friendly & energy-efficient technologies in operations, processes and plant architecture. These can be witnessed from the recent initiatives from the group which includes increasing the solar power capacity at its plant locations in Chennai to 1450 KW and Surajpur to 6200 KW. The aim is to make a wider impact and contribute to make the planet a better place for the community and future generations.

Mahindra Electric and Auroville join hands to pilot India’s first integrated sustainable mobility solution for a community

On the occasion of World Environment Day, Mahindra Electric, part of the USD 20.7 billion Mahindra Group, today inked a memorandum of understanding (MoU) with Auroville, an experimental township established in 1968 in Tamil Nadu, to pilot India’s first integrated sustainable mobility ecosystem for a community. This unique ecosystem will be an extension to Auroville’s several e-mobility initiatives over the last few decades. This is aligned with its endeavour to encourage lifestyle choices in quiet mobility, optimal sharing of resources and reduced carbon footprint, hop-on-hop-off shuttles and smart parking.

Under the aegis of the MoU, the two parties will work with IISc (Indian Institute of Science), Puducherry Smart City Development Limited, GoGreen BOV, and numerous initiatives at Auroville itself to develop a holistic ecosystem encompassing Mahindra’s electric vehicles, smart parking systems, charging infrastructure and its software integration platform NEMO. It also aims to enable mobility models like ride sharing, ride hailing, self-drive rentals etc. The Town Planner, PSCDL, supported by the French Government, will also play a key role in this initiative.

Mahindra Electric also unveiled its energy storage solution which will play a key role in enabling the ecosystem including charging infrastructure, EV parking, and an EV Support Centre. It will also help harness renewable power, thus becoming an end – to – end green solution.

Michelin’s 2048 ambitions: Michelin tyres will be made using 80 percent sustainable materials

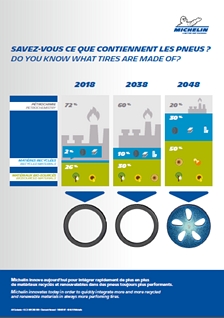

At Movin’On 2018, Michelin is announcing its ambitious plan to ensure that by 2048, all of its tireswill be manufactured using 80 percent sustainable materials and100 percent of all tires will be recycled.

Today, the world-widerecovery rate for tires is 70 percent and the recycling rate is 50 percent. Michelin tires are currently made using 28 percent sustainable materials (26 percent bio-sourced materials like natural rubber, sunflower oil, limonene etc., and 2 percent recycled materials such as steel or recycled powdered tires). For a sustainable future, Michelin is investing in high technology recycling technologies to be able to increase this content to 80 percent sustainable materials.

Sustainable Materials

The route to this ambitious sustainable material target will be achieved byresearch programs into bio-sourced materials like Biobutterfly and working with Michelin’s high-level partners, and the advanced technologies and materials that are being developed in these partnerships. The Biobutterfly program was launched in 2012 with Axens and IFP Energies Nouvelles to create synthetic elastomers from biomass such as wood, straw or beet.

Michelin is developing innovative solutions today in order to integrate more and more recycled and renewable materials in its tires, while continuing to improve performance, including 30% of recycled materials by 2048. This is demonstrated by the recent acquisition of Lehigh, a specialist in high technology micro powders which are derived from recycled tires.

Lehigh Technologies is a specialty chemical company that is part of the High Technology Materials Business Unit of Michelin. Lehigh is the leader in the market place for Micronized Rubber Powders (MRP), a sustainable raw material that reduces feedstock costs by up to 50 percent and delivers performance without compromise across a wide range of markets. Lehigh makes sustainability an unbeatable proposition – we call it ‘Green for free’.

MRP replaces oil- and rubber-based feedstocks in a wide range of industrial and consumer applications, including high performance tires, plastics, consumer goods, coatings, sealants, construction materials and asphalt. Lehigh technical experts collaborate with customers to optimize products for each application.

Lehigh operates the world’s largest MRP manufacturing plant in Tucker, Georgia, with an annual production capacity of 54,000 tonnes. Lehigh’s state-of-the-art Application & Development Center is also located in Tucker and serves as an innovation hub where Michelin conducts research and formulates MRPs in collaboration with its customers. Michelin hasfive product ranges so far, PolyDyne™, MicroDyne™, EkoDyne™, Rheopave™ and Zenoflex™, and continues to expand the range of solutions in core markets. Lehigh Spain, a joint venture with Hera Holding is based in Barcelona. The first Lehigh plant outside of the US – located in MurrillodelFruto, is under construction and will begin operations in summer 2018.

Commenting on this venture, Christophe Rahier, Director of the High Technology Materials Business Line at Michelin said: ‘This acquisition demonstrates Michelin’s strategic determination to capitalize on its expertise in high-tech materials, in areas that extend beyond the field of tires. In particular, by promoting the use of innovative recycled materials from tires in a variety of non-pneumatic industrial sectors’.

Recycling

In 2018, according to the World Business Council for Sustainable Development it is estimated that 1 billion of end of life tires are generated worldwide, representing around 25 million tonnes. Within this total, 70 percent of tires are recovered and 50 percent are recycled every year, on average. This 50 percent is the amount of recycled material, into products such as rubber used in sports surfaces, and the additional 20 percent is transformed into energy.

By comparison, 14 percent of plastic containers or packages are recovered each year, and the car industry has a target of 3.5 percent recycling rate.

Michelin is investing in high technology recycling so that by 2048 tires are 100% recycled for the vehicles of the future.

To achieve these ambitions, Michelin proposes to develop partnerships and identify new ways to recycle tires, or new outlets for recycled tires.

As a result, a Hackathon was held in 2017, in partnership with Alliapur, to brainstorm solutions in which tire granulates could be used. The winner of this Hackathon was “Black Pillow”, which suggested creating safe urban furniture made of tire granulates.

Potential Gains

When all of these ambitions are achieved – 80 percent sustainable materials and 100 percent of tires recycled – the savings will be equivalent to:

- 33 Million barrels of oil saved per year (16.5 supertankers), or 54,000 GWh.

- One month’s total energy consumption of France.

- 65 billion kilometers driven by an average sedan (8 L/100 km) per year.

- All cars in Europe driving 225 kms (291 million kms), or 54 kms for all cars worldwide (1.2 billion cars estimated).

VISION Concept

Last year at Movin’On, Michelin revealed its innovative VISION concept. Advanced materials and 3D printing technologies will be used to manufacture and renew the tread of this mobility solutionand will mean that it is 100 percent recyclable. The features of this concept which enhance its sustainability credentials:

- An airless tire made of bio-sourced and recycled products

- A connected eco-system within the tire, providing services and advice to the driver

- A bio-degradable tread that can be renewed with a 3D printer

- A mobility solution that reduces the environmental footprint of car journeys

BRIDGESTONE India and UNICEF India join hands for ‘Drops of Hope’ – A Project on Water Conservation and Drinking Water Security

Bridgestone India Pvt. Ltd, a group company of Bridgestone Corporation joined hands with The United Nations Children’s Fund (UNICEF) of India for ‘Drops of Hope’ – a Project on Water Conservation and Drinking Water Security. The partnership has been formed in collaboration with the Government of Maharashtra, Department of Water and Sanitation. The first phase of the project will be implemented in districts of Pune, Latur and Osmanabad in Maharashtra India.

Bridgestone India is contributing a sum of INR 3.9 crore to the project over a period of three years. The focus of the project is to develop robust drinking water security and safety plans which also involves a baseline survey to understand the existing situation as well as assess the future impact.

Maharashtra state has the highest drought prone blocks due to hard rock areas and shallow aquifers. Only half of rural households in Maharashtra have access to tap water of which only 63% is treated. Nearly 20% of rural household still depend on distant & unprotected sources for their domestic water supplies and nearly 1/6th of rural population depend on public hand pumps. Per capita water supply in state has huge disparities that can range from 21 ~129 liters per capita per day (lpcpd). (National Vision is minimum 70 lpcpd by 2020). This Project is planned with an objective of strengthening village level committees to find local solutions to Safety and Security Planning for Drinking Water throughout the year.

Bridgestone India will provide support to UNICEF in undertaking training and skill development of community members and key officials at the village, block and district level to build water supply structures and ensure their proper maintenance. Another key facet of this program is the use of innovative communication processes and tools to support positive behaviors towards water usage and management.

The foundation of this project is to work closely with the Government of Maharashtra to identify and leverage key resources for enhancing investments in infrastructure.

This partnership involves deployment of models that aim to create a mechanism to ensure drinking water security. Communities will be encouraged to access available funds set aside for village development which also encompasses water security.

Delta Electronics India Launched Mumbai’s first DC Fast-Charger for Electric Vehicles at Maharashtra Mantralaya

Delta Electronics India Pvt. Ltd, a leading Power and Energy management company, launched Mumbai’s first DC Fast-Charger station at Maharashtra Mantralaya.

The EV Charging Station was launched by Dr. Harsh Vardhan Union Minister for Science & Technology & Earth Sciences, Government of India and Devendra Fadnavis, Chief Minister of Maharashtra.