During a tour at Horacio Pagani’s “dream factory” , our man in Italy, Akis Temperidis took a glimpse on the brand new assembly line of Huayra and had an eye opening talk with Pagani’s PR, Luca Venturi. The reason for the visit? To get to know each other, to arrange a future interview with Horacio Pagani and guess what? A test drive of the Huayra! So keep tuned for some crazy action! In the interim, here’s a log of our experience at the assembly line of the legendary car.

The Pagani Experience

Pagani cars are built in a discreet atelier – as Pagani himself prefers to call it – well hidden in the ugly industrial area of Cesario sul Panario, a small town between Modena and Bologna – Italy (somewhere between the HQs of Ferrari and Lamborghini). From the outside, the HQ building is nothing fancy. It could well be a small furniture or shoe factory by the look of it. The difference is, the fanciest modern supercar is built inside here!

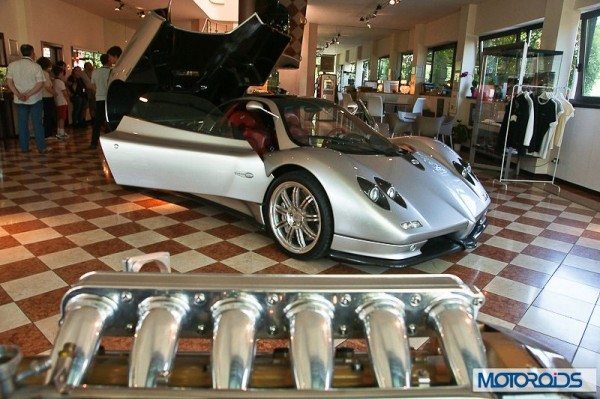

On the front there is a small but spirited show room. A silver Zonda with full red interiors is parked on the chess like floor. The showroom features a mini bike and a F2 single seater that Horacio Pagani designed and built when he was young. Various memorabilia and scale models the Argentinean made as a child are also kept in the showroom. Other highlights include a small bar with a hand-made chromium juke box that was featured at the Milano Autoshow in 2009 when Zonda R was launched, a piano on the other corner and a small merchandise store.

Pagani’s personal taste is evident everywhere – the showroom is more like his living room. Anybody can visit this place. You only need to book a visit on www.pagani.com three days in advance, pay 24 euros and get in the magic world of one of the last genuine car creators. If you are lucky, you might see Mr. Pagani himself during your visit.

The day I visited Pagani, Horacio himself was not there but I was well accepted by Luca Venturi, the bright young Public Relations officer from Verona who works with Pagani for the last three years and seems very happy about this.

Luca took me around the carbon fiber atelier, let me take pictures almost everywhere in the holy place and then took me to the brand new assembly line two blocks away in the same industrial area.

“Pagani is a dedicated person, addictive for his creativity and passion”, Luca tells me. “It is very inspiring working with him”. The PR guy wrote a thesis about Pagani communication and marketing for his diploma.

When Horacio saw the work, he recruited him. “I started from low, making copies and small jobs”, Venturi admits. The Argentinean genius designed everything from motorbikes to racing cars and from bar furniture to caravans and in his home country before he moved to Italy in 1983. He chose to live next to via Emilia, just to be close to the great supercar brands, like Lamborghini. He worked for the company for the next 10 years, even after he created Modena Design, his own studio, in 1991 Horacio was in the project team of the LM002, the monstrous Lambo SUV that failed to get an order by the US army.

Later he designed the Countach Anniversary – the ultimate version of Marcello Gandini’s ’71 supercar – and got involved in the development of the – carbon fiber based – Diablo. From 1993, Horacio started working on his own supercar he wanted to name Fangio – thanks to his personal friendship with his compatriot five-time F1 World Champion. Six years later the car was named Zonda because in the meantime JMF had passed away and Pagani didn’t want to exploit his name, for his respect to Fangio’s family.

We could go on with the personal story of a man considered as the Leonardo da Vinci of the automotive industry but we‘d better do it when we talk to him. For the time being, take a look at the photo gallery we prepared from our visit to one of the holiest places of the Italian motor valley. To dream about a car like this is for free!

10 things to know about Pagani Huayra

– Huayra project was initiated in 2003. Total project budget is 20 million euros.

– The car was conceived to be homologated for US and Japan from scratch.

– 90 Huayra’s are already ordered. 25 Huayra will be built in 2013 and 40 under schedule in 2014.

– There are 18 Pagani dealers worldwide, three in the USA.

– Horacio Pagani owns 93% of the company. The rest belongs to Zappacosta family, founders of Logitech.

– 75 people work for Pagani, 8 in the style center that headed by Horacio himself.

– 67 people work on the Huayra V12 engine at AMG.

– 4.700 parts comprise Huayra. All made or designed by Pagani.

– The basic price of Huayra? 989.500 euros (Approx. Rs 8 crore) plus VAT.

– The road test for every car before delivery is only 20 kilometers.

– A Huayra R will be presented soon!

Click Next for a detailed image gallery with Captions >>>