One of the oldest mechanics working with Pagani. “We were like a family in the first years” he told us.

Titanium screws are used in the Huayra for weight saving. We were told that the Milan made screws for the prototype cost 80.000 euros!

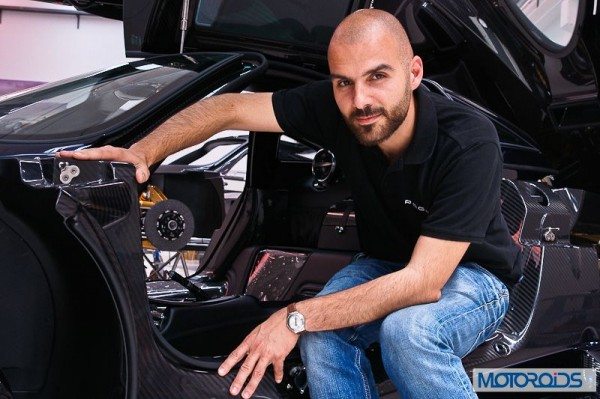

Luca Venturi, the PR Manager was recruited by Horacio Pagani after he completed his university thesis on the Pagani company.

Pagani was a pioneer in advanced composites since the ’80’s when he worked on the Lamborghini Countach Evoluzione, the first carbon fiber made production car.

Sixty seven people work in AMG exclusively for building the Huayra V12 engine. Every unit is assembled and signed by a specific mechanic.

The AP Racing clutch disc

Body painting is outsourced but still of absolutely amazing quality

Even if the gearbox lever is an electric switch, Pagani designed a complicated leverage underneath just to give the right, mechanical feel to the driver.

Of course you can order your Huayra in natural carbon fiber look.

The Huayra sign is forged from a single aluminiun piece.

The push rod rear suspension with specially made “gold” shocks by Ohlins.

All parts in the Huayra are designed by Pagani. Massive Brembo calipers included!

A nearly complete Huayra in the new assembly line that is white and clean like a clinic!

Next page to continue the virtual tour>>>

,,,,,,,,,,,,,,,,,,,,,,.

,,,,,,,,,,,,,,,,,,,,,,.