Last time, we saw how scale models came in to being and its history. This time we will understand how they get evolved.

The creation of a scale model (we are not referring to toy models) is time intensive and expensive. It typically takes 2-6 months (depending on the scale size) for a miniature collectible to be produced. Larger the scale size, more the detailing and so longer the time it takes.

PROCESS

Conceptualization: The designer locates the subject model and digs in to its history. If the model is currently in production, then it’s easy. All measurements are taken of the subject (bike, car or a truck). Alternatively, hundreds of photos from various angles are studied in conjunction with closer observation of carpet/dashboard textures, engine / grille detailing, door handles, audio controls, colour scheme, etc.

But if it is a vintage or non-existing model, then the designer has to depend on obtainable photos and several library resources. This is a herculean task and it is only expertise & experience that play the role.

Use of CAD (Computer Aided Design) and CAE (Computer Aided Engineering) programs is used extensively to induce the right form or shape. The final picture of the model is deduced.

Prototype: This is the primary step towards actual production. It is typically created in clay that is skilfully crafted by experience hands. A resin prototype is then made to examine any additional flaws. After approval, this is sent for making a steel mould that is milled out of a hard steel block.

Die Moulds: The word die-casting comes from this step as casting is done when hot metal Zamac* is poured in to the hollow form of the mould and allowed to cool so it will solidify, thereby giving it the necessary shape. The die moulds are heavy (some weigh up to 500 kg) and have to be perfect as the shape of the model depends on the way the steel mould has been cast.

Steel Die Mould

Models that are made in resin come out of room temperature vulcanized (RTV) silicone rubber moulds. In resin casting, the mould is filled with synthetic resin (usually polyurethane) that is mixed with a curing agent. Because of an exothermic reaction, it generates a lot of heat resulting in castings being formed. It is then removed from the mould with the help of a ‘releasing agent’ (a type of chemical that prevents the casting to get stuck to the mould) and then cooled.

Silcone rubber mould

* Zamac is an alloy that is a mixture of Zinc, Aluminium, Magnesium & Copper

First Shot: Before the factory begins production, 2-3 pieces are made. They are called “first shot” and are produced to examine full integration of the metal body with other engine parts and interiors. Once approved, full scale production of the model begins.

Painting & Printing: Once the scale models are produced, each are painted with the help of spray guns before they go for drying. Finally, pad printing (also called Tampo machine) is used to print decals and other labels.

TYPES

Most models come in 2 types – metal and resin. There are also few makers of plastic & tin (also known as white metal) models but this percentage is small. No one makes cast iron or steel models these days.

Metal models that are made in steel moulds give larger yields (more produce). So, given the cost of dies (between Rs. 10-15 lakhs) larger quantities have to be made to keep costs low. They are more sturdier in construction and the probability of breakage is lesser during transportation. Therefore, most of the products available in the market are metal scale models.

Metal cast model

Resin models are expensive as they are made in fewer quantities since rubber moulds can churn out only 25-150 pieces before the mould loses its shape & form. Though they are brittle in nature they offer a higher degree of detailing – finger print impressions can be made. Though one cannot open its doors, bonnet and boot, they are still a favourite among growing number of collectors. When one talks of detailing, resin models win hands down over others.

Resin cast model

Next time, we will go through different scale sizes and what one should essentially collect. Until then….. happy collecting.

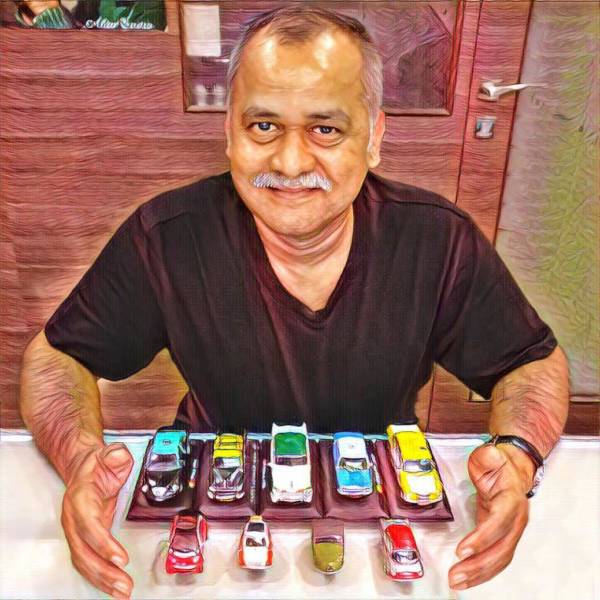

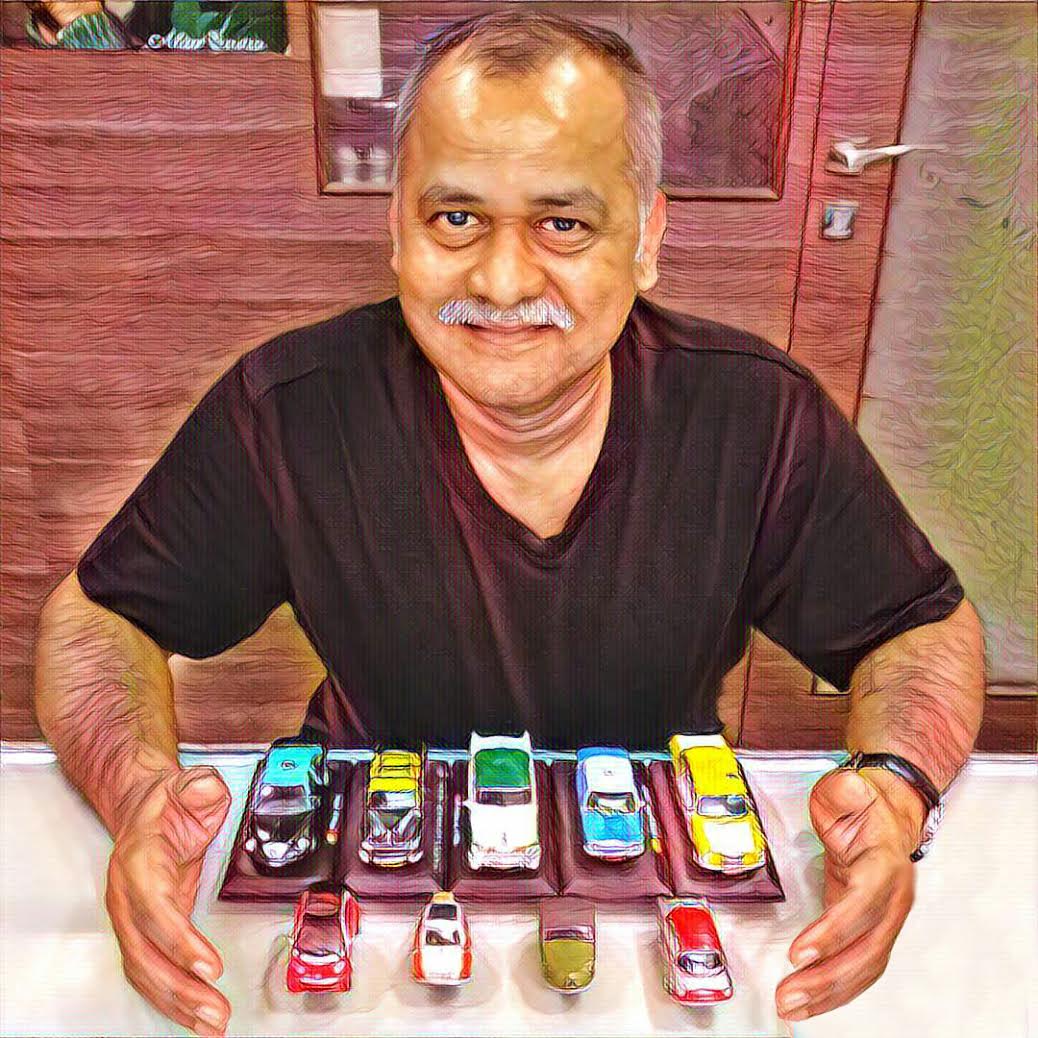

Subrato Sen is a welding engineer by profession and an avid scale model collector. His initiation as a scale model collector occurred as a school boy in 1978 when he got a BOAC (former name of British Airways) airlines coach made by Maxwell (Indian brand) from his parents; an item that he still, with pride, possesses. Models & brands that are lesser known are his speciality. He has a penchant for collecting automotive car & truck models from COMECON countries, steam-driven vehicles before 1900 and has a huge collection of taxis & buses from most cities of the world.

Currently, he lives in a suburb of Mumbai and continues together with his passion. He also runs an online scale model business. You can buy scale models from his website scalemodelcart.com

Disclaimer : The opinions expressed within this article are those of the author. The article does not reflect the views of Motoroids and Motoroids does not assume any responsibility or liability for the same. The images used in the article have been provided by the contributor. Motoroids doesn’t claim the copyright for the images used.