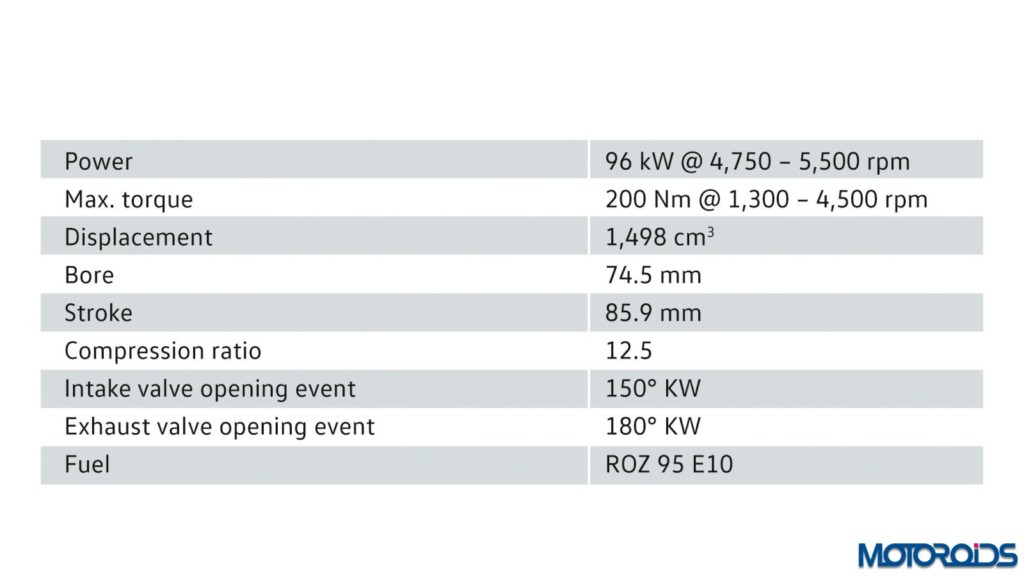

Volkswagen has unveiled its new generation EA211 TSI evo engine at the 37th International Vienna Motor Symposium. The first model in the new generation engine lineup is the 1.5-litre TSI, expect to launch in late 2016. The engine will be presented in two states on tune initially, producing 130hp and 150hp.

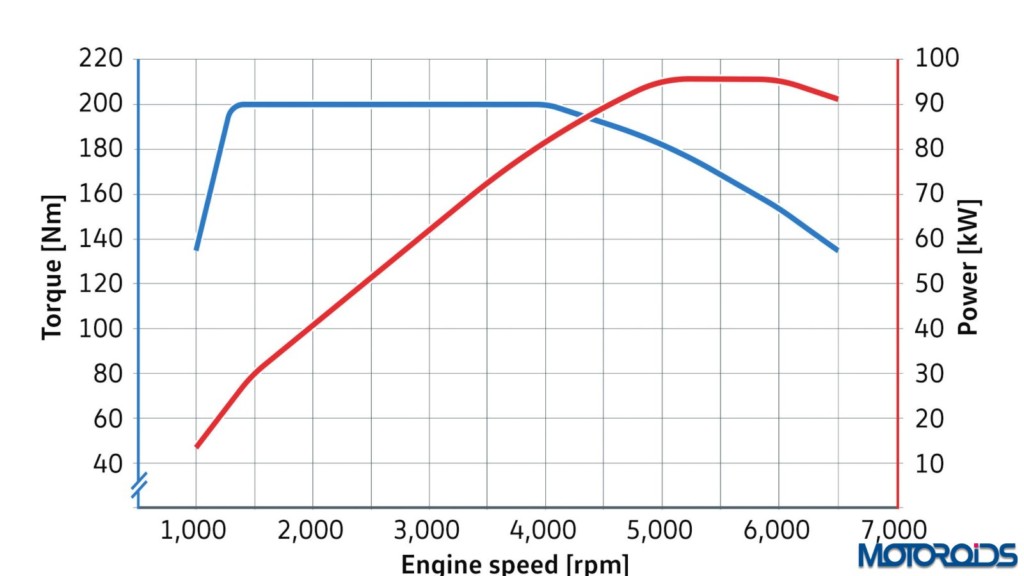

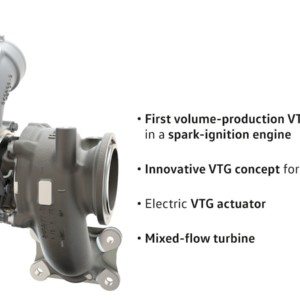

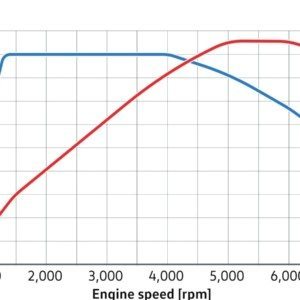

The new engine features several firsts, including variable turbine geometry for a turbocharger, a first for a mass produced spark-fired petrol engine. The new engine also gets several new technical innovations, as a result, the peak toque is available extremely early (from 1,300 rpm) and over a broad range of engine.

The fuel efficiency is also claimed to have been significantly enhanced, by up to one litre over one hundred kilometres. This is up to 10 percent better than the previous 1.4 litre TSI engine. Volkswagen is claiming that the improvements in fuel economy do not merely apply under test conditions but also during everyday driving.

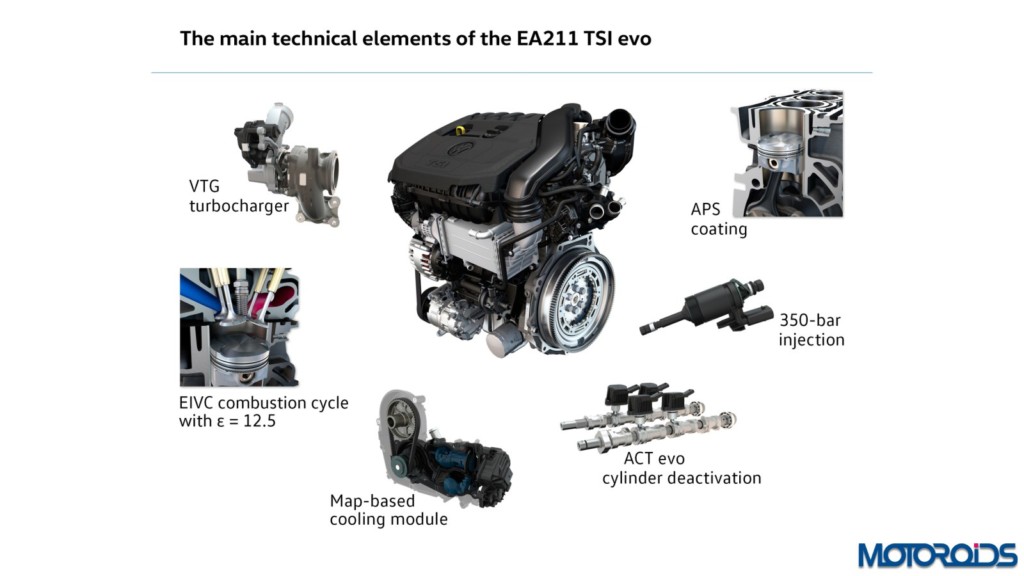

The new engine features the following new technologies

- Turbocharger with variable turbine geometry (VTG)

- Common-rail injection system with up to 350 bar pressure

- Miller combustion cycle with a high compression ratio of 12.5:1

- Innovative thermal management

- Cylinder deactivation (ACT)

- APS-coated cylinder walls (atmospheric plasma spray)

The cylinder head has been extensively re-engineered, with the water jacket optimized and the valve angle and combustion chamber adapted for the best possible execution of the Miller combustion process.

The Miller combustion cycle is a key innovation in the new EA211 TSI evo. The resulting improvement in thermodynamic efficiency has been systematically implemented through four main development targets:

- The geometric compression ratio has been increased to improve efficiency

- The final compression temperature has been reduced through early intake valve closing and resulting expansion cooling in the intake stroke.

- The charge motion has been optimised for rapid flame propagation to reduce knocking

- Increase in charge density through efficient exhaust gas turbocharging

The new VTG turbine, in combination with a reduced moment of inertia in the turbocharger means that the maximum torque arrives some 35 per cent faster.

The diameter of the injector tip is reduced to 6 mm, which is beneficial for integration into the combustion chamber, improves stiffness and reduces temperatures at the injector plate. The fourth-generation Volkswagen direct- injection system sess increase in injection pressure to 350 bar. The resulting smaller droplet size improves mixture formation, leading to benefits such as a substantial reduction in particulate emissions.

The cylinder deactivation, another subassembly from the EA211 engine assembly kit, has been improved and is entering volume production with the TSI evo. It closes off the intake and exhaust valves of cylinders two and three up to the mid-load range, while at the same time deactivating fuel injection.

The cylinder liners in the aluminium crankcase are coated using the APS process (atmospheric plasma spray). This significantly reduces friction, enhances heat dissipation, reduces knocking and makes the engine more resistant to poor-quality fuels on global markets.

Expect the new engine to make it to VW Group cars as early as the end of this year. It may replace the engines on cars such as the Skoda Octavia which are currently propelled by the 1.4 TSI powerplant.