Shell unveiled its concept city car which, if it were ever to go into production, could deliver material reductions in energy use in the road transport sector. The three seater car is tangible proof of energy efficiency improvements that can be achieved by using modern technology available today through a process of “co-engineering” whereby vehicle body, engine design and lubricants are all created together.

Independent testing and a rigorous life-cycle study shows that Shell’s Concept Car would deliver a 34% reduction in primary energy use over its entire lifecycle when compared to a typical city car available in the UK. The Shell Concept Car would use around half the energy required to build and run than a typical small family car available in the UK and 69% less than that of a typical sports utility vehicle available in the UK

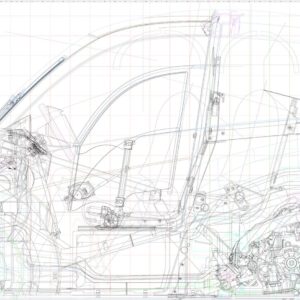

The new car is the result of a co-engineering collaboration between some of world’s leading vehicle, engine and lubricant designers, with each of the three elements of the vehicle tailored to work optimally with each other. It takes a holistic view on energy reduction focusing on design material selection; reduced energy demand via aggressive downsizing, and streamlining while enhancing the efficiency of energy delivery through innovative engine design and lubricant formulation to minimise the impact in terms of overall energy lifecycle use.

The car’s gasoline consumption has been measured using a range of vehicle testing protocols covering both steady state and urban driving styles. Sample test results include a steady state consumption of 107 miles per gallon [2.64Litres per 100km] [38km/Litres] [89.1 miles per gallon US] at 70kmph/45mph and an improvement of 4.67g CO2/km on the New European Driving Cycle (NEDC) from the use of bespoke lubricants, equivalent to a 5% improvement in fuel efficiency compared to standard lubricants available in the UK.

Shell provided all the fluids for the car, specially ‘designing’ the motor oil to complement and enhance the overall efficiency of the vehicle, principally by minimising friction. Shell’s Lubricants technology team created bespoke engine oil, based on its premium product Shell Helix Ultra with PurePlus Technology. In parallel, engine guru Osamu Goto’s group at Geo Technology optimised the three cylinder petrol engine by re-designing and optimising many of the internal engine components associated with friction. On the cold portion of the NEDC, these fluids reduced CO2 emissions by 7.1% and on the combined cycle by 5.0%, compared to standard lubricants available in the UK, again highlighting the value of co-designing engine and fluids.

The Shell Concept Car is a total rethink of the Gordon Murray Design T.25 city car produced in 2010 for which Shell produced a prototype oil to improve the vehicle’s energy efficiency. The concept uses Gordon Murray Design’s patented iStream platform. The car weighs just 550kg and is built using carefully chosen materials which have a low energy and CO2 footprint. A number of the car’s components were created using 3D printing to accelerate the construction of this prototype vehicle. The car also uses recycled carbon fibre for its body that can be assembled for a quarter of the price of a conventional steel car and almost the entire car can be recycled at the end of its life.

The car makes use of a modified version of Shell’s Drive App via a smartphone. This App provides the driver with real time feedback via an on-screen graphic which emphasizes the fact that fuel consumption is highly dependent on driver’s behaviour.

Check out the new concept in the official video below.