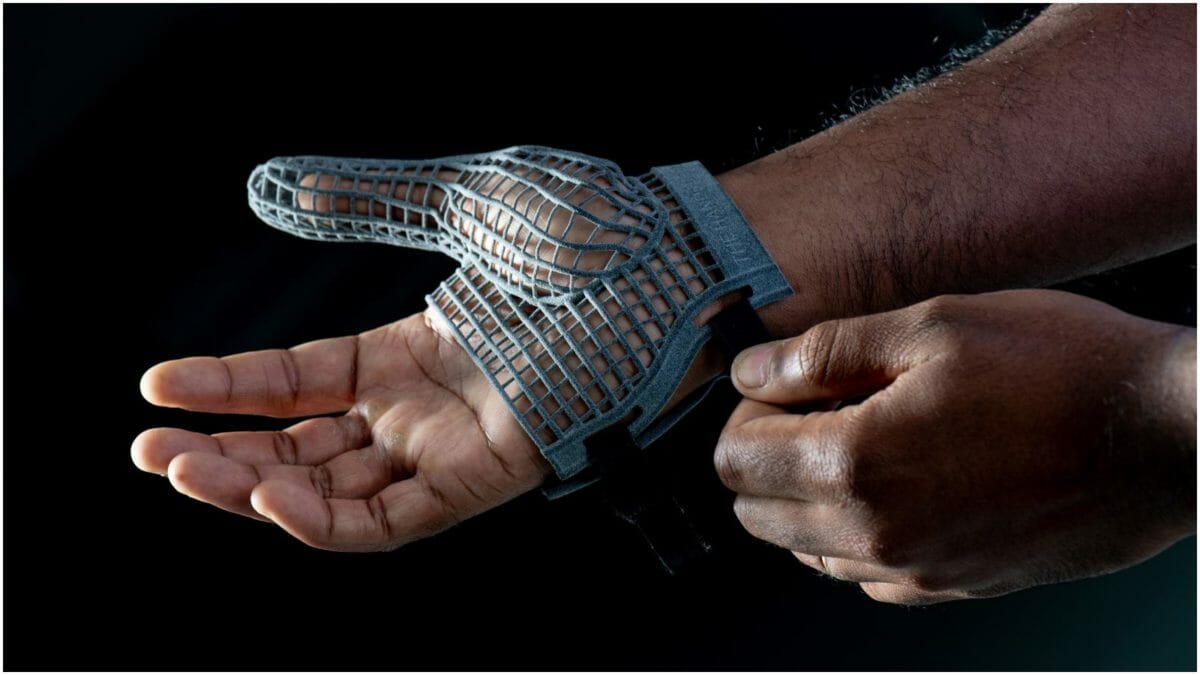

Jaguar Land Rover recently developed a new type of glove using a 3D printer, which can be an important contribution in the next generation of protective workplace clothing. This lightweight 3D-printed glove can help the employees protect themselves from the threat of a musculoskeletal disorder. The 3D glove is specially designed for people working on the production line, and for those required who fit clips or fasteners into the chassis during the assembly of Jaguar and Land Rover’s luxury vehicles.

According to research, Musculoskeletal disorders include more than 100 different types of conditions, making up around 30% of all workplace injuries that result in time off and account for a third of the money paid in compensation to employees. This disorder can affect over 10% of the global population, rising to as much as 40% in certain industries. Which is why, engineers at Jaguar Land Rover’s Gaydon site, home to one of the largest 3D printing facilities in the UK – saw an opportunity to use the company’s advanced manufacturing expertise to design and 3D print a lattice-style structure which would provide support to reduce muscle fatigue, but also be flexible and comfortable enough to wear during an eight- hour shift. The team modelled designs in different densities using a 3D computer-aided design (CAD) software and a variety of materials for testing.

Also Read: Lego Group’s Latest Scale-Sized Creation Is The All-New Land Rover Defender

Following feedback from the trials, the team then worked on a second-generation prototype., that include a foam pad made using impact additive D30. D30 is a polymer material which absorbs impacts when placed under pressure. This will make the glove suitable for those who fit parts, such as door casings, using the palm of the hand. In the short term, these gloves will support workers across Jaguar Land Rover’s facilities, helping to protect against the growing number of musculoskeletal disorders.

Also Read: JLR’s New Sensory Steering Wheel Prevents You From Getting Distracted

Chris Noble, Additive Manufacturing Strategic Engineer for Jaguar Land Rover, said: “The health and wellbeing of our workforce remain our priority across all factories and facilities. Technologies like the 3D-printed glove allow us to use the world-leading expertise and equipment we have in-house to protect the hands of our makers, developing equipment that will make Jaguar Land Rover a great place to work, now and in the future.”