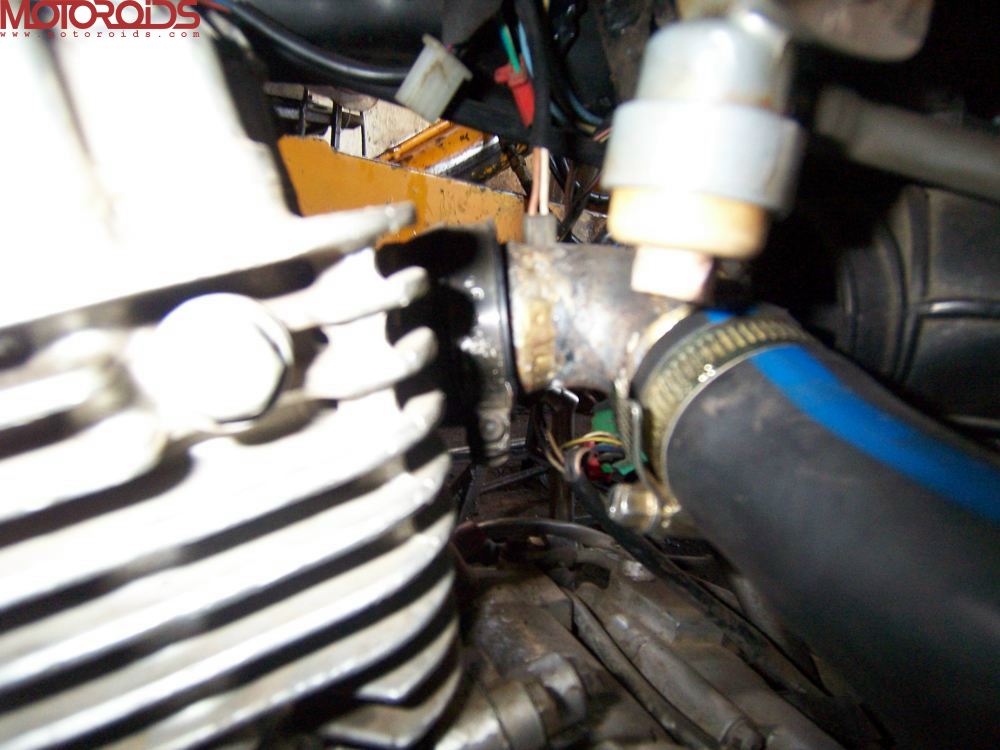

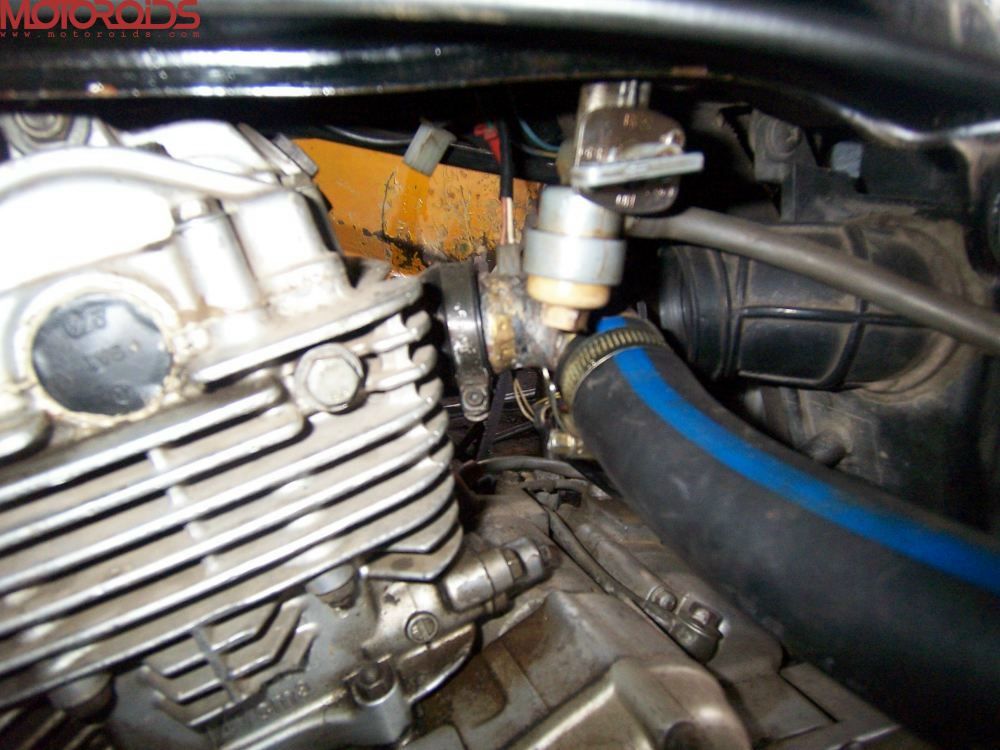

A team of students from Malnad College of Engineering,Hassan have created a supercharger for a 150cc motorcycles as their final year project. Titled “Design and fabrication of Supercharger for a single cylinder engine”, the project was used to install and test a self-fabricated supercharger for Fiero 150cc motorcycle.

The bike was duly tested with and without the supercharger and the results were documented in the most professional manner possible. The team of engineering students who worked on the project included

- Gautam J

- Mithun S K

- Suhas P

- Kiran Mitra

An attempt was made to increase the power output and volumetric efficiency of the engine by using a supercharger. The objective of this project is to attain a higher powered engine at a lower cost compared to that of a higher capacity engine. Here we have a few more details about the project, followed by some pictures of the installed equipment and the test results

Consideration for our Design and Farication

A boost of 0.5bar

Selection of material:

Casing: Mild Steel

Mild steel has been used for the casing due to its wide availability, strength, high thermal conductivity and low co-efficient of friction with Teflon.

Rotor: Steel

Steel is used for the rotor due to its high strength, durability, high thermal conductivity and low co-efficient of friction with Teflon.

Vane: Teflon

Teflon is used as material for the vanes due to its low co-efficient of friction with steel of about 0.04, less weight and its ability to withstand high temperatures.

Shaft: Mild Steel-EN24

Mild Steel EN24 is used as material for the shaft due to its high torsional stiffness and shear strength.

TEST RESULTS

RESULTS AND DISCUSSIONS

The design, fabrication and assembly of all the parts have been discussed earlier. Various tests were carried out on a chassis dynamometer for a stock vehicle and with the supercharger and the corresponding results are tabulated below.

6.1 Engine specification (Suzuki Fiero):

| Type |

: |

Single cylinder 4-stroke air cooled |

| Cubic capacity |

: |

147.50cc |

| Maximum power |

: |

12bhp @ 7500rpm |

| Maximum torque |

: |

10.50N-m @ 6500rpm |

| Bore × stroke |

: |

57mm × 57.8mm |

| Compression ratio |

: |

9.4:1 |

| Transmission |

: |

4 speed gear |

6.2 Stock vehicle (without supercharger):

6.2.1 Speed test:

|

Gear |

Max. speed(kmph) |

|

1 |

35 |

|

2 |

40 |

|

3 |

74 |

|

4 |

108 |

6.2.2 Acceleration test:

|

Speed(kmph) |

Time(sec.) |

|

01-50 |

5.60 |

|

01-60 |

6.00 |

6.2.3 Fuel consumption test:

|

Gear |

Speed(kmph) |

Fuel consumption(kmpl) |

|

1 |

25 |

20.50 |

|

2 |

40 |

32.70 |

|

3 |

60 |

34.10 |

|

4 |

70 |

54.10 |

6.2.4 Power test:

|

Speed(kmph) |

Torque(N-m) |

Speed(rpm) |

Power(KW) |

|

Loading |

|||

|

80 |

13.00 |

1736 |

2.36 |

|

70 |

17.50 |

1517 |

2.78 |

|

60 |

20.80 |

1307 |

2.84 |

|

50 |

22.10 |

1124 |

2.60 |

|

40 |

26.20 |

919 |

2.52 |

|

30 |

26.10 |

696 |

1.90 |

|

Unloading |

|||

|

30 |

24.00 |

767 |

1.92 |

|

40 |

26.70 |

882 |

2.46 |

|

50 |

22.70 |

1100 |

2.61 |

|

60 |

19.40 |

1374 |

2.79 |

|

70 |

16.00 |

1588 |

2.66 |

|

80 |

13.70 |

1761 |

2.53 |

6.3 Supercharged vehicle:

6.3.1 Speed test:

|

Gear |

Max. speed(kmph) |

|

1 |

36.2 |

|

2 |

41.8 |

|

3 |

74.4 |

|

4 |

108 |

6.3.2 Acceleration test:

|

Speed(kmph) |

Time(sec.) |

|

01-50 |

4.9 |

|

01-60 |

5.2 |

6.3.3 Fuel consumption test:

|

Gear |

Speed(kmph) |

Fuel consumption(kmpl) |

|

1 |

25 |

13.80 |

|

2 |

40 |

26.30 |

|

3 |

60 |

29.60 |

|

4 |

70 |

44.40 |

6.3.4 Power test:

|

Speed(kmph) |

Torque(N-m) |

Speed(rpm) |

Power(KW) |

|

Loading |

|||

|

80 |

13.60 |

1720 |

2.45 |

|

70 |

18.40 |

1520 |

2.92 |

|

60 |

22.60 |

1308 |

3.09 |

|

50 |

24.30 |

1110 |

2.82 |

|

40 |

28.50 |

924 |

2.75 |

|

30 |

28.13 |

689 |

2.02 |

|

Unloading |

|||

|

30 |

26.90 |

756 |

2.12 |

|

40 |

28.85 |

857 |

2.59 |

|

50 |

25.10 |

1119 |

2.94 |

|

60 |

21.33 |

1344 |

3.02 |

|

70 |

17.12 |

1568 |

2.81 |

|

80 |

14.50 |

1752 |

2.66 |

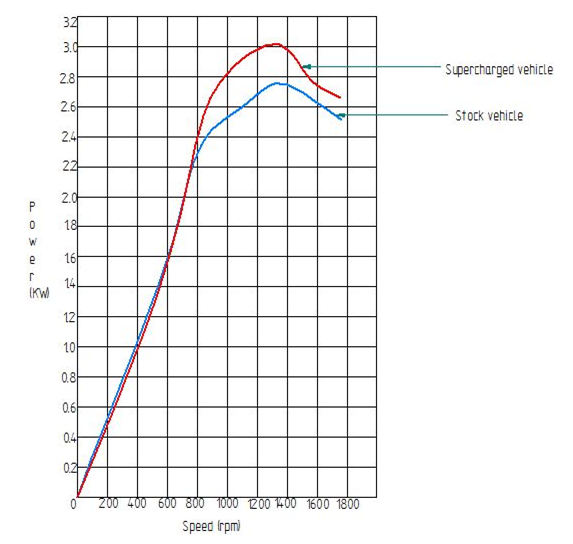

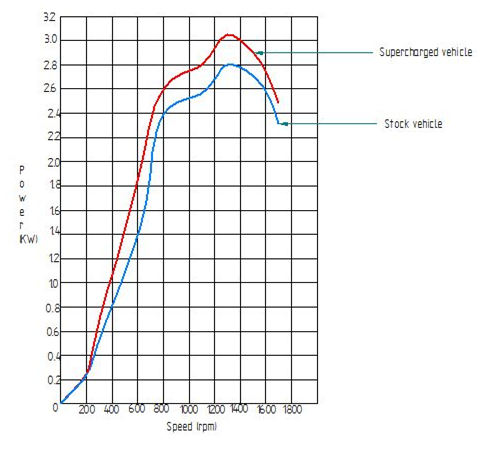

6.4 Power v/s speed curves:

(a) Loading curve

(b) Unloading curve

The results showed a significant improvement of power in the low speed range, but there was little improvement at higher speeds. Also an improvement in the maximum speed and acceleration was obtained. The fuel consumption was higher due to larger amount of a/f mixture being supplied to the engine and also due to drive being taken from the engine.

CONCLUSION

7.1 Conclusion:

Based on the results, the following conclusions can be drawn:

- The supercharger unit was designed for a 4-stroke single cylinder 150cc engine.

- The supercharger unit worked effectively and was found applicable for low powered engines.

- The installation of the supercharger unit provided a significant power output.

- The maximum speed of the vehicle was increased.

7.2 Scope for future work:

An intercooler has to be fitted in between the outlet of the supercharger and the engine manifold to dissipate the heat in the charge, thus increasing the charge density. Also the carburetor needs to be tuned and the ignition timing needs to be retarded. The draw through type supercharger can be changed to a blow through type by placing the carburetor in between the charger and the engine manifold which requires a fuel pump and helps improve the efficiency of the carburetor.