With the effects of Global Warming being noticed in worldwide climatic change, there has been an increase in the number of Green enthusiasts. They now try to save and reuse every bit of the Earth’s natural resources—from sourcing electricity from solar panels to reusing water in gardening. The reason? We have been depleting the planet’s resources faster than it can regenerate for decades now. If you believe in the same, you are not alone in your quest for a Better World. In Chennai, Ford has been relentlessly implementing Green practices at its integrated manufacturing facility in its quest for sustainability.

“We at Ford India have been making conscious efforts towards a sustainable future via the various green practices that we are following. Courtesy path breaking green manufacturing processes we have been able to re-use 100% of the waste water generated in the plant, enabled a 30% reduction in water consumption per car production in the past three years and have reduced electricity consumption per car by 10%. In the plant, 100% of the hazardous waste generated is either recycled or co-processed in the cement industries – making it a zero landfill plant” said P Senthil Kumar, vice president, Vehicle Operations, Ford India.

Ford India’s Chennai plant is the first Ford car plant in the world – and Ford is the only manufacturer in India – to use new the Three-Wet High-Solids paint technology. Automated robots apply all three coats – primer, base coat and clear coat – one on top of another before oven curing.

The plant also enables heat recovery by utilizing exhaust heat air to heat fresh air through the Heat exchanger in Topcoat oven and E coat ovens. Propane gas has been introduced as a fuel in the ovens instead of diesel, making for an environment-friendly paint process.

The 3-Wet High Solids technology also resulted in following benefits:

· VOC emission reduction by 60% since 2009, best in the Ford Asia Pacific region

· Dock-to-Dock time reduction by 40%

· CO2 emission reduction by 21%

· Water consumption reduction by 15000 KL/ annum

The energy saved in the paint shop – 27.6 million kWh/annum – is enough to power almost 12,000 households in Chennai for a year, or to light up the entire Chennai street lights in the night for about 4 months.1

1.0L EcoBoost engine – The latest green invention

The latest green invention by Ford that will be made available in India in the soon to be launched EcoSport is the 1.0L EcoBoost engine.

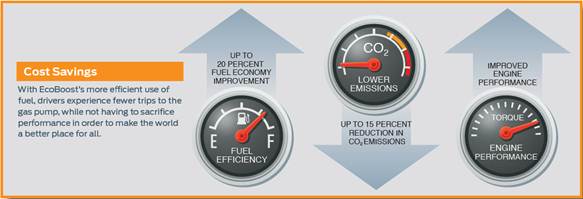

The 1.0L EcoBoost engine is unlike any engine in Ford’s 109-year history. Not only is it the company’s first three-cylinder engine, but it also debuts many new technologies never before seen in a Ford vehicle. The integration of three advanced technologies (turbocharging, direct injection and Ti-VCT) into the EcoBoost delivers significant customer benefits:

· Optimized engine efficiency: delivers up to a 20% improvement in fuel economy, 15% reduction in carbon dioxide emissions compared with conventional gasoline engine

· Superior driving performance: strong low-end torque and responsive performance across the full rev range

· Advantages of small displacement: large-engine performance, but with the size, weight and fuel economy of a much smaller unit

The 3-cylinder, 1.0L EcoBoost engine is so compact, it can be transported as “hand luggage”. The engine in the bag is purely the bare block, without any of the essential engine peripherals – including the all-important turbocharger. It was required to be lifted from the bag and placed into a plastic tray – much like anyone does with their laptops while going through security at the airport.

The 1.0L EcoBoost engine was unanimously awarded the ‘2012 International Engine of the Year’ by 76 global journalists.

Ford India has kept reducing energy consumption and boasts of being the best in Ford World on energy conservation. As per the roadmap outlined for energy reduction starting from 2012, Ford expects a 25 % reduction in energy usage per vehicle, which helps to reduce Carbon foot print.