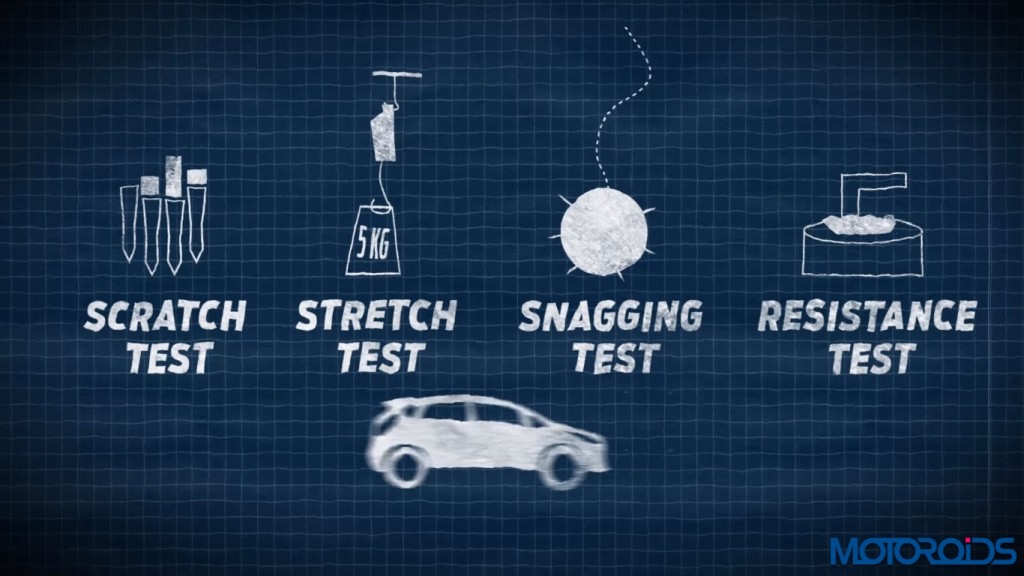

Throughout a vehicle’s lifetime, it’s inevitable that the materials inside a car show signs of wear and tear. In order to ensure the long-term durability and suitability, folks at Ford have their own ways of testing their fabric and materials that go into their cars. They put every material used inside Ford vehicles to a series of tests where the materials are stretched, scratched, snagged, sniffed and even splashed with the likes of grease, dirt and hot coffee, to see how they will stand up against the test of time.

Some of the tests carried out in Ford’s lab are as follows-

Odour Test

Samples of each material are placed in individual jars that are heated up in ovens for up to 24 hours at three different temperatures to simulate different real-life situations. They even heat the oven as high as 65°C to make sure the car doesn’t develop stronger scents even when it is baking under the sweltering summer sun. Fresh out of the oven, the examiners sniff each of the materials and rank them according to the degree any smell is noticeable. If a material is ranked poorly, it gets sent straight back to the supplier.

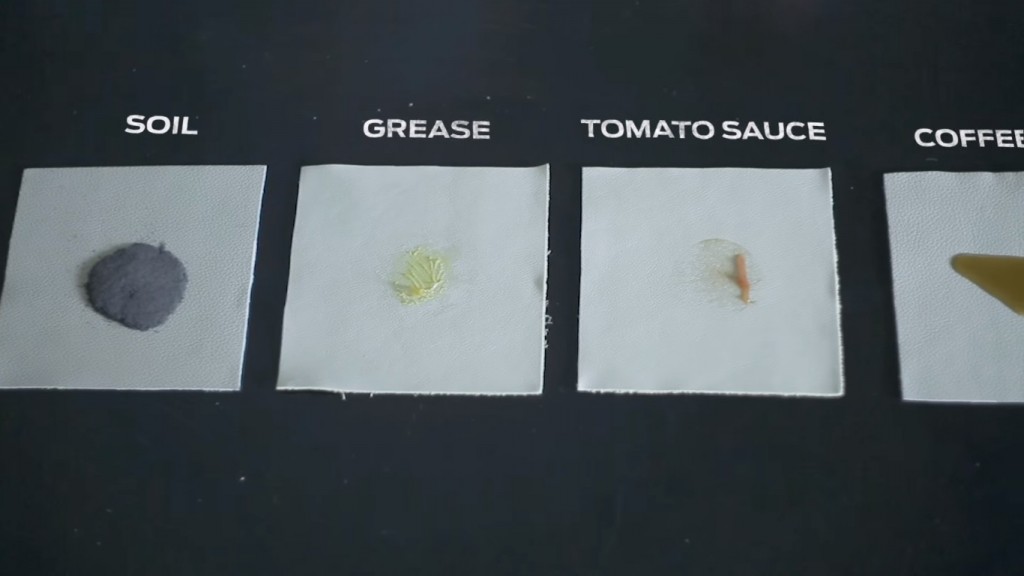

Soiling and Clean-abilityTest

Common everyday items like mud, hot coffee, ketchup and grease, are purposely spilled on seat fabrics to test the stain resistance of these materials. The stains are left to sit there for anywhere between 30 minutes up to 24 hours before cleaning them off. The samples are then examined for any signs of discoloration. This test helps engineers ensure Ford’s seat fabrics are highly resistant to stains so consumers don’t have to stress over accidental drops and drips in their car.

Mace Snagging Test

In this test, the mace, a small spiky iron ball, repeatedly strikes the surface of the fabric as it spins nearly 600 times in 30 minutes. After the test is completed, engineers examine the fabric and compare the results to reference images to determine if the outcome is acceptable or not.

Stretch and Set Test

At Ford, engineers test the materials that go into every Ford vehicle for durability by stretching it to great lengths to see it can still be able to return back to their original state. The materials are hung with a 12.25 kg weight attached to their bottom to see how much they stretch and recover afterwards.

Bally Flex Test

Much like the Stretch and Set Test, this test repeatedly prods pieces of leather (nearly 100,000 times!). This oddly hypnotic test makes sure that even after continual poking and prodding, cracks, peels or tears don’t sneakily show up on the leather interior of your car.

Resistance to Dye Transfer test

Ford engineers actually rub materials of different colours – namely blue denim – against car seat leather to see if the colour gets transferred onto the leather. Blue jeans might well be the single most popular piece of clothing for men and women worldwide, but they are also a car seat’s worst nightmare. Jeans are notorious for leaving behind an unsightly blue hue on new light colour leather car seats.

Five-Finger Scratch Test

This test has “fingers” of different weights that are run over the plastic to scratch its surface. The scratch that’s left behind is examined to make sure that marks are as imperceptible as possible.

Here are some videos explaining the tests carried out by Ford.

Splash

Sniff

Snag

The carmaker sure does put some unusual efforts to test their materials that are used. These tests look fancy and interesting and the fabrics are showcased to withstand all the abuse with ease in the labs. But how well they really do or fail when put into a real life conditions? Let us know your experiences and views through the comments sections below!