4-Point Overview:

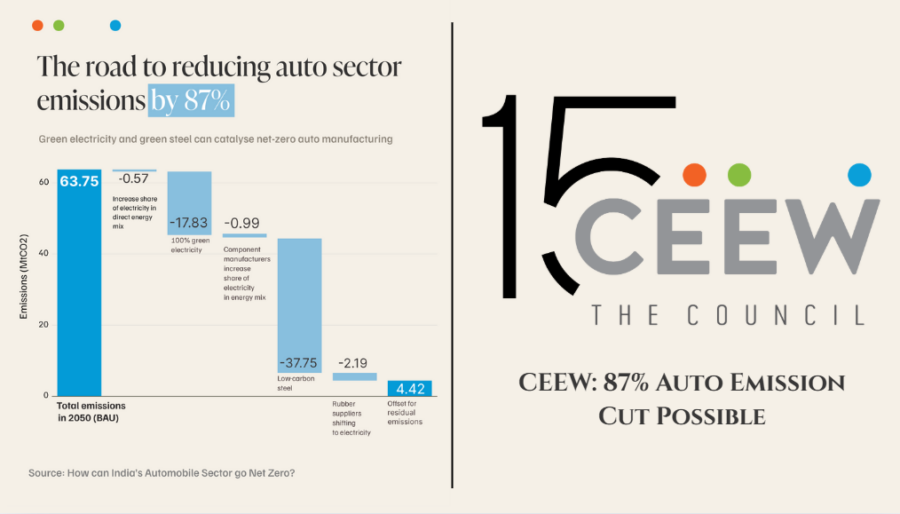

- India’s auto industry can slash its manufacturing emissions by 87% by 2050.

- The key? Switch to clean electricity and low-carbon steel.

- A new CEEW study reveals that 83% of emissions come from the supply chain, not just factories.

- Brands like Tata, Mahindra, Toyota, and BMW are already moving in this direction.

Introduction: What Happens Before a Car Hits the Road?

When we think about making cars cleaner, we usually picture electric vehicles zipping down highways with zero tailpipe emissions. But what about the pollution caused before the car is even built — in the factories, steel plants, and rubber suppliers?

That’s where the real problem lies. And that’s exactly what a powerful new study by CEEW (Council on Energy, Environment and Water) wants the world to focus on.

According to the study, India’s auto industry — the third-largest globally — has a golden opportunity: by shifting to green electricity and low-carbon steel, we can reduce emissions from vehicle manufacturing by a massive 87% by 2050.

Let’s break it down.

Where the Emissions Really Come From

The CEEW study explains that most automakers only track emissions from their own factories (Scope 1) and electricity use (Scope 2). But the real culprit? Scope 3 emissions — which come from suppliers making steel, rubber, plastics, and other materials using fossil fuels.

In India, Scope 3 accounts for over 83% of emissions from auto manufacturing. That means even the greenest EVs are carrying a dirty manufacturing legacy unless things change upstream.

What Needs to Be Done?

To fix this, auto companies and their suppliers must go all in on clean production. Here’s what CEEW recommends:

- Use 100% renewable electricity — solar, wind, etc. — to run auto plants.

- Shift steel production to use hydrogen instead of coal.

- Grow the use of scrap-based recycled steel to 48% by 2050.

- Rubber and component suppliers should also switch to green energy.

If these steps are taken, total manufacturing emissions can fall from a projected 64 million tonnes of CO₂ to just 9 million by 2050.

Who Are Proactive?

The good news? Major players are waking up. Brands like Mahindra, Tata Motors, TVS, BMW, Mercedes-Benz, Ford, and Toyota are already committed to the Science-Based Targets initiative (SBTi). This means they’re serious about becoming net-zero by 2050.

But making the shift will take more than pledges — it’ll take serious procurement plans, green steel demand at scale, and long-term policy support.

What About Hybrids?

The study also looked at hybrid vehicles as a “bridge” to EVs. While hybrids may reduce fuel consumption short term, they still rely on combustion engines. So, for true decarbonization, EVs must take the lead — and be made sustainably.

Summary Table of the Report:

| Key Element | Current State | Future State (2050 Target) |

|---|---|---|

| Vehicle Production | 25 million units/year (2020) | 96 million units/year (2050) |

| Manufacturing Emissions | 64 MtCO₂ (projected BAU scenario) | 9 MtCO₂ (if green electricity & steel adopted) |

| Scope 3 Emission Share | Over 83% of total emissions | Vastly reduced with green steel, recycled inputs |

| Steel Emission Reduction | Dominant source of emissions | -38 MtCO₂ by using low-carbon methods |

| Renewable Power in OEMs | Partial use | 100% required |

| Green Steel Share | Minimal | 56% hydrogen-based steel, 48% scrap-base |

Conclusion: Build Clean, Not Just Drive Clean

India’s automobile industry is at a once-in-a-generation crossroads.

We’ve spent years talking about making vehicles greener. But now it’s time to make the way we build vehicles greener too. From the mines that extract the iron to the steel plants and rubber factories — everything must move toward cleaner, smarter, and more sustainable production.

Because the truth is: if we really want to drive into a cleaner future, we can’t just electrify the car. We have to green the entire process.

And that shift? It starts right now.